Trailed Sprayers

Showing all 5 results

-

Compact Sprayer Trailer. Unmatched Mobility – 300L

Compact Sprayer Trailer. Unmatched Mobility – 300L

The Compact 300L 12 volt trailer is ideal for use behind an ATV motorbike or utility vehicle. The trailer features rotationally moulded UV resistant poly tanks with a complete drain sump, 8” (540mm OD) turf wheels, 4 stud mini hubs, 12v Shurflo 20 l/min 90 psi pump with a pressure regulator and gauge, 15m steel hose reel with quality pistol grip gun and adjustable nozzle with 50mm tow ball coupling. All packaged on a robust full RHS frame. Compact 300L can be fitted with a 4m steel/aluminium folding boom. -

Prairie Rowcrop Sprayer 1500-3000L

Prairie Rowcrop Sprayer 1500-3000L

Prairie Rowcrop represents the latest in technology and features in a package that is simple to operate, yet strong and durable. Spanning four main tank capacities across two different chassis frame sizes, there is a sprayer to suit almost every requirement.

EZ Control Station

The EZ control station places all the filling and flushing functions in the one convenient location. All valves are colour coded and clearly labeled for easy identification and operation.

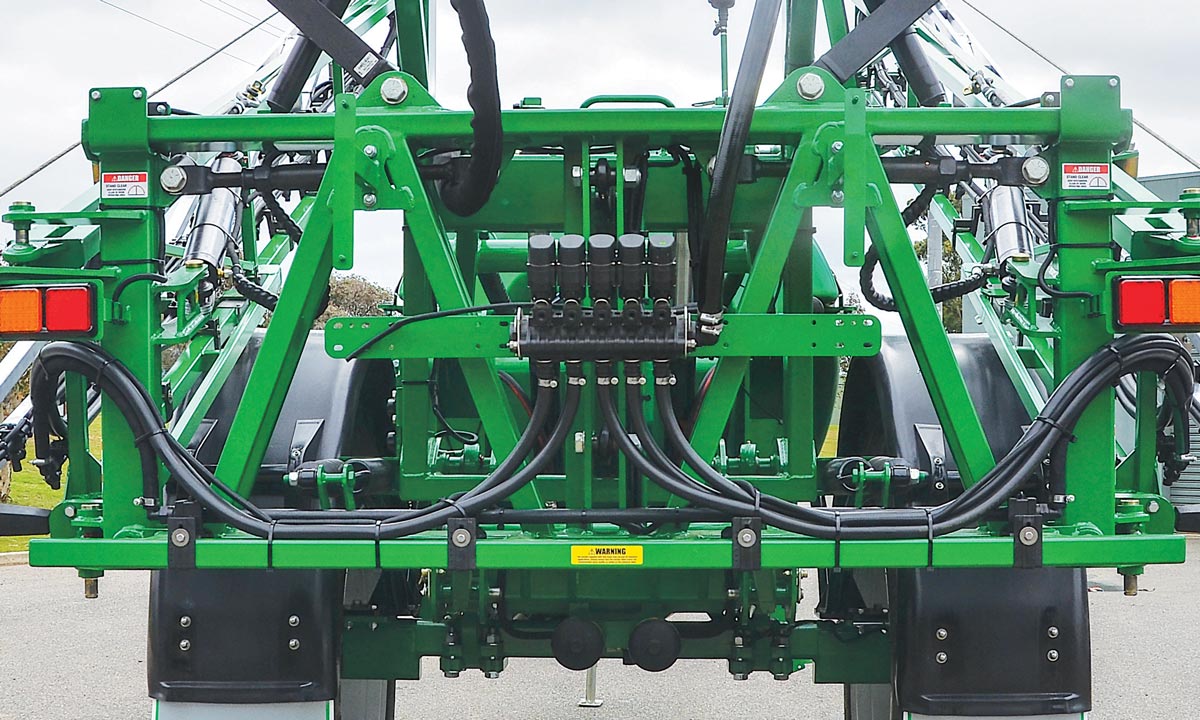

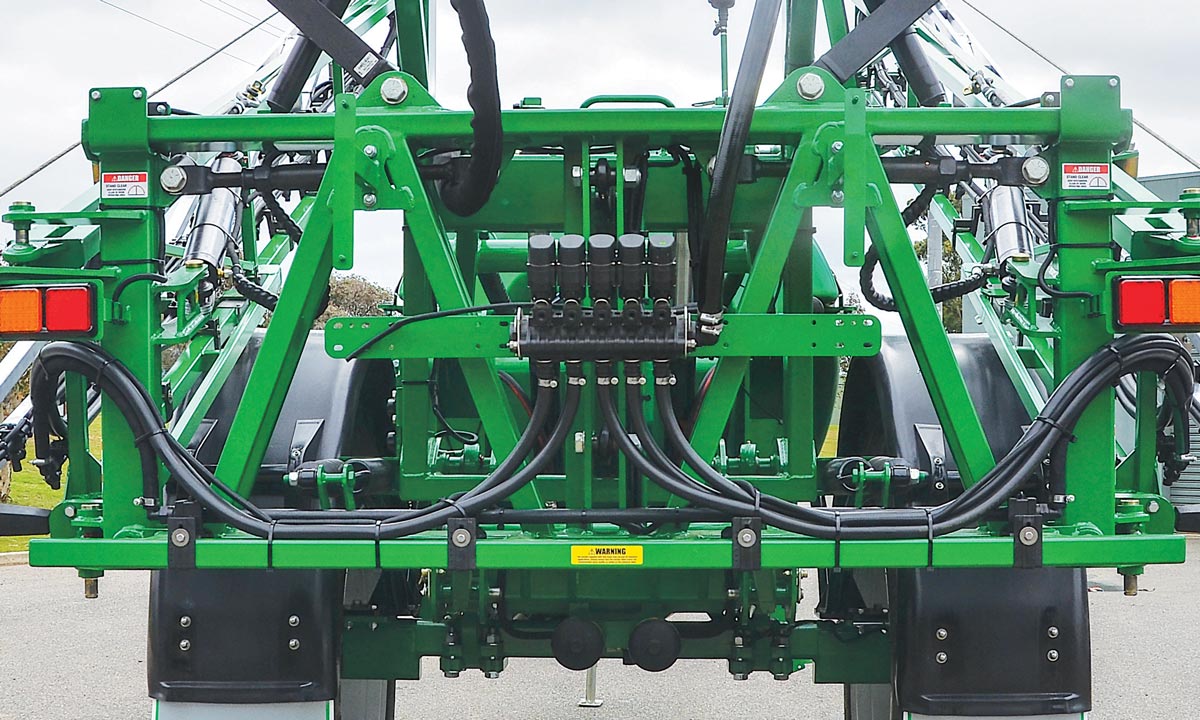

Boom Section Valves

High quality motorised boom section valves with ¾” delivery lines provide quick nozzle start and stop capability. Standard in 3 sections with ability to upgrade to more sections as required.

Axle and vertical boom suspension

Oversize 70 series, 8 stud axles with heavy duty dust seals provide years of trouble-free service. Nitrogen charged hydraulic accumulators provide vertical boom suspension and dampening.

Diaphragm Pumps

Smooth running 540 rpm oil backed diaphragm pumps are constant displacement providing consistent flow, largely unaffected by changes to operating pressure. Main tank agitation is consistent, even when large changes to operating pressures are made.Options

Boom wing tilt

Individual side boom wing tilt enables the operator to quickly raise the boom wing tip up over obstacles such as fences or tree stumps.

Induction hopper

Lower the hopper into the loading position by simply releasing the spring loaded catch, enabling you to load powders, granules & liquids fast using a large flow venturi system.

The lower valve has a large handle that’s easy to grip while wearing PPE and features drum rinse nozzle, tank flushing nozzle and simple tank level calibration.

Hydraulic drive

80cc geroler hydraulic motor option replaces the PTO shaft. Complete with rpm sensor for accurate in-cab pump speed readout.

Full length poly mudguards

Covering 180 degrees of the wheel and manufactured from UV stable polyethylene plastic, these mudguards provide the best protection for your sprayer, also fitted with heavy rubber mudflaps which prevent mud build up on the boom.

Rowcrop Hitch

Turning is important. Tight, difficult turns at the end of rows can use up a large amount of spraying time. A turntable hitch which permits tighter turning, speeds up spraying where there are narrow plantings or boundaries near the end of rows.Call us control freaks!

In today’s fast-changing precision farming landscape it is easy to be left behind in the technology stakes.

That’s why Goldacres make it easy, with multiple solutions to suit the basic requirements to the top end needs.

For more than two decades Goldacres have relied on Raven to provide complete flow control systems with matched components to give quite simply, unmatched flow control accuracy and stability.

At the heart of the control system is a positive displacement pump run at constant rpm. This creates known flow rates across varying pressures, essential for accurate and stable flow control. In addition, two system critical components, a flow meter and three way regulator valve* combine to help achieve fast “on target rate”, plus greater flow stability with known tank agitation.

The Prairie Special range of sprayers feature three controller types to suit all requirements.3 way electric section and regulation control system

For simple fuss-free flow and section control the 1500-2500L small frame Prairie Special can be fitted with a three section switch box with electric pressure regulation, this allows the operator to adjust the spray pressure to achieve the desired nozzle flow rate. The operator then drives at a set ground speed to maintain the correct application rate.

SCS450 Auto rate control system

The proven SCS range of sprayer consoles provide simple, fuss-free control of the flow control duties. The SCS450 features up to 5 boom section control, 2 pre-set auto rates plus manual pump speed readout, ground speed and several counters. If you are looking to further expand the capabilities, then the SCS range is compatible with all the leading automatic section controllers on the market.ISO BUS Auto rate control system

Tractor cabins can get very busy with the vast range of systems requiring individual control consoles. The ISO BUS standard virtual terminal (VT) brings all the systems together into the one display. Essentially each system contains the brains, while the VT is simply the interface between the two. This means only one operator console is required.

Goldacres offer the option for ISO BUS compatibility, allowing numerous leading VT displays to take over the sprayer control duties. Features like flow control pressure, pump speed readout, plus all tractor steering and task control applications can all be all monitored by the one display.Construction

To build the best sprayer you have to start with a solid platform

The small frame Prairie Special design incorporates many elements to ensure maximum strength, longevity and performance. Features such as, fully bushed pivot points, precision laser cut components and the best corrosion proof paint system. Fully welded in rotating positional jigs ensures accuracy, repeatability and quality all combined with the experience gained with thousands of sprayers in the field.

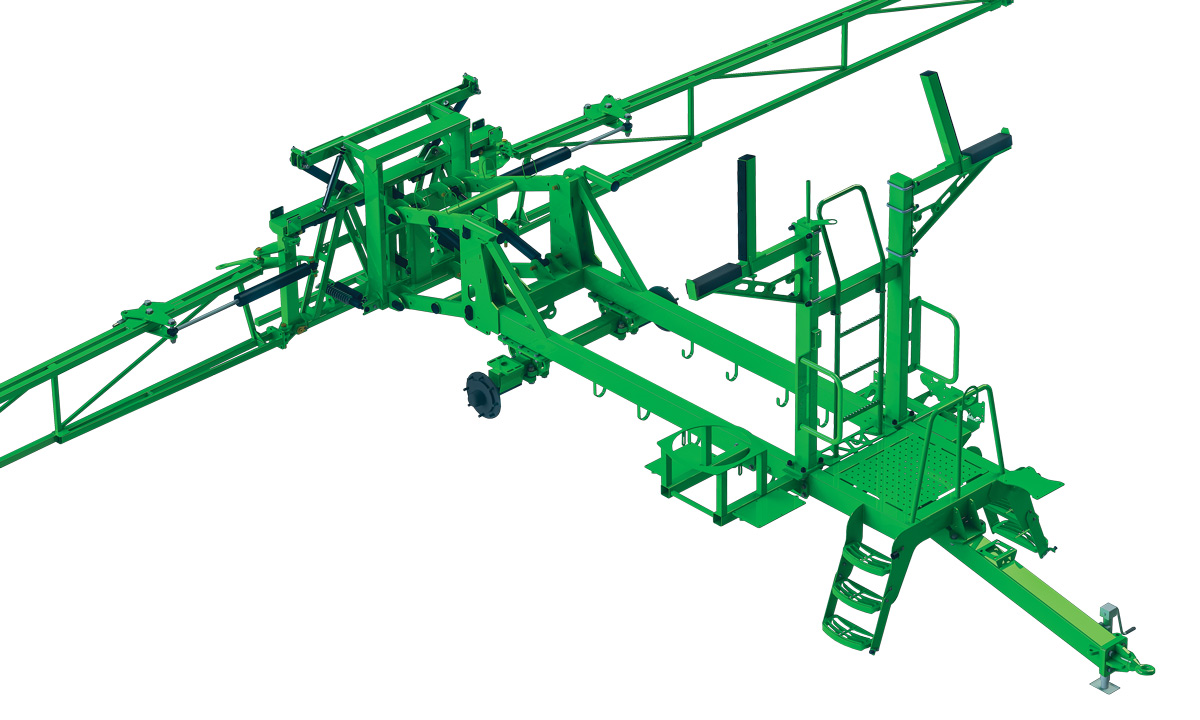

- Chassis. Manufactured from high strength heavy walled 125x75x6mm RHS to minimise flexing and provide a stable platform for boom mounting. The rear chassis section features an integrated boom and tank support (3000L version only). Long wheel base (axle to drawbar) provides excellent boom yaw stability and reduces sideways pushing forces at the tractor.

- Drawbar pull. Single 150mm square drawbar section allows tighter headland turning. Full 360 degree swivel forged tow eye ensures maximum articulation between sprayer and tractor. Walk through platform. Access the main tank easily and safely from either side of the sprayer. No need to walk around the sprayer or tractor to access the other side. Open foot treads provide safe access to platform in muddy conditions. Lower portion of treads fold up out of the way when not in use.

- Boom rest. The adjustable height boom rests with rubber supports provide a soft contact point for the boom wings, minimising the chance for damage.

- Boom parallelogram lift. The mechanism provides boom height adjustment as well as the vertical suspension.

- Delta boom centre section. Using lightweight trussing techniques the boom centre section is light yet extremely strong. All high load pivot points are greaseable, ensuring a long service life and optimum boom suspension performance.

- Paint and anti-corrosion system. All major components are fully grit blasted using a fractured steel shot, essential for excellent paint adherence. The bare steel components are then treated using a high build filler primer which flattens the blasted surface. All un-welded joints are seam sealed then top coated using Goldacres’ exclusive chemical resistant paint formula. Finally all components are baked in a high temperature oven until fully cured. All zinc plated pins and bolts on the boom are coated with rust preventative G15, which adds another level of corrosion protection.

- Full modular construction. The full modular construction technique allows many options to be easily added at the time of build or at a later date as required. Dealer Fit Options (DFO) can be retrofitted without the need for welding or drilling existing components.

Delta booms

Application made easy

The Delta boom range is ideal for growers looking to benefit from the proven stability and performance of the three way suspension system in an economical package. Designed for light to medium duty applications with widths ranging from 15m to 24m*, there is a size to suit every situation. Standard features include mild steel inner wings with lightweight aluminium outer wings, single operation boom folding system featuring the proven cable control with outer wing break back functionality, full size ¾” boom lines to minimise pressure drop across the sections for consistent spray application and full hydraulic lift and fold.Krono booms

The Krono & Krono Premium represent the finest in European boom technology

Ideal for rowcrop applications, the booms feature a compact construction with hydraulic fold and can be operated as single sided or bi-fold to give a range of operating widths. The booms feature self levelling suspension with a manual adjuster fitted to the 12m and hydraulic tilt adjustment on the Krono Premium. 500mm plumbing is standard, other plumbing options available upon request. Both booms feature breakaway end tips.

Chemical handling

SuperFlow 40 Induction Hopper

Lower the hopper into the loading position by simply releasing the spring loaded catch, the SuperFlow hopper enables you to load powders, granules and liquids fast – up to 20 kg/min* (Atrazine) using a large flow venturi system. The lower valve has a large handle that’s easy to grip while wearing PPE and features push down drum rinse nozzle, tank flushing nozzle and simple tank level calibration.Transcal (not shown)

The 45L Transcal is a simple and effective way of transferring and measuring liquid chemical. Using a venturi the Transcal can draw chemical from an open container using a probe, or out of an envirodrum, to provide a totally enclosed transfer system. The Transcal measures chemical transferred by volume, not flow, providing accuracy regardless of the liquid viscosity.Venturi Probe

Standard on all models across the range, the probe is a simple method of transferring chemical into the main tank directly from a drum. It uses a venturi mounted in the main product tank. -

Prairie Compact S Broadacre Sprayer Trailing 400-600L

Prairie Compact S Broadacre Sprayer Trailing 400-600L

The Prairie Compact S incorporates many elements from the larger Goldacres trailing sprayer range to ensure maximum strength, longevity and performance. Engine & Pump

Engine & Pump2.8hp Honda GX100 petrol engine coupled with a Udor diaphragm Iota 20 l/min 290 psi pump

Sight tube

Tanks feature clear sight tubes that are calibrated in 50L increments to give a clear reading of the tank volume.

Mudguard

Plastic mudguards fitted with mudflaps

Hose reel

Water / chemical, steel housing, 30m hose length, 3/8” hose diameter, 300 psi / 20 bar max pressure.

Gun

AA30 Gunjet pistol grip gun.

Sump

Sump for complete draining of product tank. -

Prairie Compact Broadacre Sprayer Trailing 1000-2500L

Prairie Compact Broadacre Sprayer Trailing 1000-2500L

The Prairie Compact trailed sprayer is built on a strong platform to handle the roughest of terrain.

Pressure manifold control station

The pressure manifold control station clearly places all the functions in the one convenient location. All valves are colour coded and clearly labelled for easy identification and operation.

Udor Zeta 85

Udor Zeta 85 features chemical resistant components such as desmopan for the pump diaphragms and stainless internal components ensuring great pump life. Available as pto or hydraulic driven option.

Suction filter

A high flow suction filter with 50 mesh screen is plumbed with a 3 way ball valve to allow suction from fresh water tank.

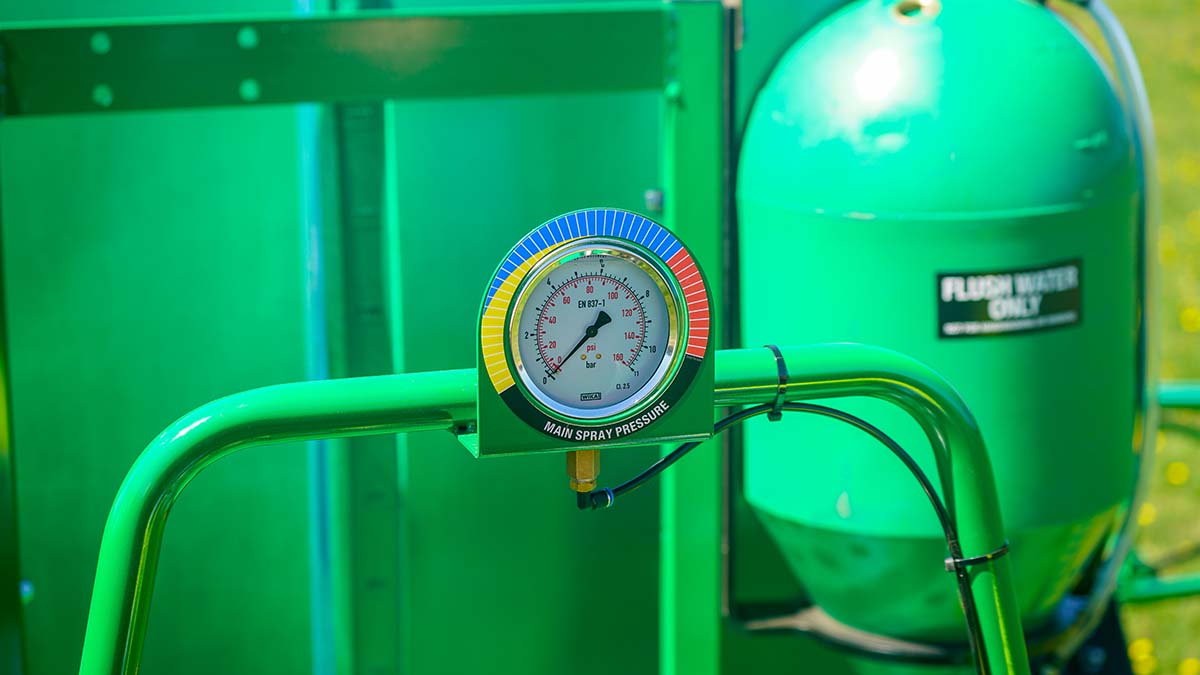

Spray pressure gauge

Centrally mounted with large face the pressure gauge allows the operator to keep an eye on system pressure easily.

Chassis

RHS construction, engineered for Aussie conditions.

Axle

Width adjustable reinforced with 8 stud hubs and 14.9 x 24 wheels. -

Prairie Special Broadacre Sprayer Trailing 1500-3000l

Prairie Special Broadacre Sprayer Trailing 1500-3000l

The small frame Prairie Special is a fully featured sprayer efficiently packaged in a layout to suit pasture, horticultural and dryland cropping applications. Based on design principles developed over 40 years of sprayer manufacturing, Goldacres delivers a proven performer, time and time again. The small frame Prairie Special comes in four tank capacities, 1500L, 2000L, 2500L & 3000L with fully hydraulic Delta booms ranging from 12 to 24m* in width. Large diameter single wheel options coupled with multiple boom configurations means it’s the logical choice.Features

EZ Control Station

The EZ control station places all the filling and flushing functions in the one convenient location. All valves are colour coded and clearly labelled for easy identification and operation.

Boom Section Valves

High quality motorised boom section valves with ¾” delivery lines provide quick nozzle start and stop capability. Standard in 3 sections with the ability to upgrade to more sections as required. Axle and vertical

Axle and vertical boom suspension

Oversize 70 series, 8 stud axles with heavy duty dust seals provide years of trouble-free service. Nitrogen charged hydraulic accumulators provide vertical boom suspension and dampening.

Diaphragm Pumps

Smooth running 540 rpm oil backed diaphragm pumps are constant displacement providing consistent flow, largely unaffected by changes to operating pressure. Main tank agitation is consistent, even when large changes to operating pressures are made.trong>

Boom wing tilt

Individual side boom wing tilt enables the operator to quickly raise the boom wing tip up over obstacles such as fences or tree stumps.

Induction hopper

Lower the hopper into the loading position by simply releasing the spring loaded catch, enabling you to load powders, granules & liquids fast using a large flow venturi system.

The lower valve has a large handle that’s easy to grip while wearing PPE and features drum rinse nozzle, tank flushing nozzle and simple tank level calibration.

Hydraulic drive

80cc geroler hydraulic motor option replaces the PTO shaft. Complete with rpm sensor for accurate in-cab pump speed readout.

Full length poly mudguards

Covering 180 degrees of the wheel and manufactured from UV stable polyethylene plastic, these mudguards provide the best protection for your sprayer, also fitted with heavy rubber mudflaps which prevent mud build up on the boom.Construction

To build the best sprayer you have to start with a solid platform

The small frame Prairie Special design incorporates many elements to ensure maximum strength, longevity and performance. Features such as fully bushed pivot points, precision laser cut components and the best corrosion proof paint system, fully welded in rotating positional jigs ensures accuracy, repeatability and quality all combined with the experience gained with thousands of sprayers in the field.- Chassis. Manufactured from high strength heavy walled 125x75x6mm RHS to minimise flexing and provide a stable platform for boom mounting. The rear chassis section features an integrated boom and tank support (3000L version only). Long wheel base (axle to drawbar) provides excellent boom yaw stability and reduces sideways pushing forces at the tractor.

- Drawbar pull. Single 150mm square drawbar section allows tighter headland turning. Full 360-degree swivel forged tow eye ensures maximum articulation between sprayer and tractor.

- Walk through platform. Access the main tank easily and safely from either side of the sprayer. No need to walk around the sprayer or tractor to access the other side. Open foot treads provide safe access to platform in muddy conditions. Lower portion of treads fold up out of the way when not in use.

- Boom rest. The adjustable height boom rests with rubber supports provide a soft contact point for the boom wings, minimising the chance for damage.

- Boom parallelogram lift. The mechanism provides boom height adjustment as well as the vertical suspension.

- Delta boom centre section. Using lightweight trussing techniques the boom centre section is light yet extremely strong. All high load pivot points are greaseable, ensuring a long service life and optimum boom suspension performance.

- Paint and anti-corrosion system. All major components are fully grit blasted using a fractured steel shot, essential for excellent paint adherence. The bare steel components are then treated using a high build filler primer which flattens the blasted surface. All un-welded joints are seam sealed then top coated using Goldacres’ exclusive chemical resistant paint formula. Finally all components are baked in a high temperature oven until fully cured.

All zinc plated pins and bolts on the boom are coated with rust preventative G15, which adds another level of corrosion protection. - Full modular construction technique allows many options to be easily added at the time of build or at a later date as required. Dealer Fit Options (DFO) can be retrofitted without the need for welding or drilling existing components.

Rowcrop

The small frame Prairie Special can be optioned with practical features suited to Rowcrop spraying.

Horticultural Rowcrop spraying is far more intensive than broadacre, with tight headlands, narrow wheel tracks and higher water rates required to do an efficient spray job. Option your Prairie Special with the Rowcrop Hitch to allow for over 90 degree turning articulation at the end of each row. 11.2 R44 (270/95R44) Rowcrop wheels can be fitted to suit 64” wheel track centre. Large capacity Zeta 260MI pump can be fitted with a hydraulic motor drive to allow for turnable hitch and higher water rates.ll-us-control-freaks" class="content__product-boxes__product-box product-box has-image">Call us Control Freaks!

In today’s fast-changing precision farming landscape it is easy to be left behind in the technology stakes.

That’s why Goldacres make it easy, with multiple solutions to suit the basic requirements to the top end needs.

For more than two decades Goldacres have relied on Raven to provide complete flow control systems with matched components to give quite simply, unmatched flow control accuracy and stability.

At the heart of the control system is a positive displacement pump run at constant rpm. This creates known flow rates across varying pressures, essential for accurate and stable flow control. In addition, two system critical components, a flow meter and three way regulator valve* combine to help achieve fast “on target rate”, plus greater flow stability with known tank agitation.

The Prairie Special range of sprayers feature three controller types to suit all requirements.3 way electric section and regulation control system

For simple fuss-free flow and section control the 1500-2500L small frame Prairie Special can be fitted with a three section switch box with electric pressure regulation, this allows the operator to adjust the spray pressure to achieve the desired nozzle flow rate. The operator then drives at a set ground speed to maintain the correct application rate.

SCS450 Auto rate control system

The proven SCS range of sprayer consoles provide simple, fuss-free control of the flow control duties. The SCS450 features up to 5 boom section control, 2 pre-set auto rates plus manual pump speed readout, ground speed and several counters. If you are looking to further expand the capabilities, then the SCS range is compatible with all the leading automatic section controllers on the market.ISO BUS Auto rate control system

Tractor cabins can get very busy with the vast range of systems requiring individual control consoles. The ISO BUS standard virtual terminal (VT) brings all the systems together into the one display. Essentially each system contains the brains, while the VT is simply the interface between the two. This means only one operator console is required.

Goldacres offer the option for ISO BUS compatibility, allowing numerous leading VT displays to take over the sprayer control duties. Features like flow control pressure, pump speed readout, plus all tractor steering and task control applications can all be all monitored by the one display.sprayer-is-only-as-good-as-its-boom" class="content__product-boxes__product-box product-box has-image">A sprayer is only as good as its boom

Today’s sprayers are full of bells and whistles which makes spraying a whole lot easier, comfortable and efficient, but it’s easy to forget what the end goal is. Precise chemical application.

Boom control can be the difference between a good spray result, and no result at all. Goldacres understand this and it is why all our sprayer designs are centred around the boom first and foremost.Why do Goldacres booms ride so well?

Goldacres pioneered the use of lightweight aluminium in the outer boom wings over two decades ago. The philosophy was, and still is today, that mass on a boom is fine so long as it is as close to the centre as possible. Reduced mass on the boom extremities reduces boom forces in both yaw and roll. This combined with the unique boom suspension results in a very stable boom ride, regardless of the terrain.

TriTech booms are contour following, meaning that the boom level will be referenced to the sprayer chassis and not purely on gravity such as a pendulum boom. This allows the sprayer to transverse the sides of hills and contours whilst keeping the boom level to the ground at all times. This results in placing the nozzle at the optimum height above the target.lta-booms" class="content__product-boxes__product-box product-box has-image">Delta booms

Application made easy

The Delta boom range is ideal for growers looking to benefit from the proven stability and performance of the three-way suspension system in an economical package. Designed for light to medium duty applications with widths ranging from 15m to 24m*. Standard features include mild steel inner wings with lightweight aluminium outer wings, single operation boom folding system featuring the proven cable control with outer wing break back functionality, full size ¾” boom lines to minimise pressure drop across the sections for consistent spray application and full hydraulic lift and fold.*24m on 3000L and larger onlyemical-handling" class="content__product-boxes__product-box product-box has-image">

Chemical handling

SuperFlow 40 or 60L Induction Hopper

Lower the hopper into the loading position by simply releasing the spring-loaded catch, the SuperFlow hopper enables you to load powders, granules and liquids fast – up to 20 kg/min* (Atrazine) using a large flow venturi system.

The lower valve has a large handle that’s easy to grip while wearing PPE and features push down drum rinse nozzle, tank flushing nozzle and simple tank level calibration.Transcal (not shown)

The 45L Transcal is a simple and effective way of transferring and measuring liquid chemical.

Using a venturi the Transcal can draw chemical from an open container using a probe, or out of an envirodrum, to provide a totally enclosed transfer system.

The Transcal measures chemical transferred by volume, not flow, providing accuracy regardless of the liquid viscosity.

Venturi Probe

Standard on all models across the range, the probe is a simple method of transferring chemical into the main tank directly from a drum. It uses a venturi mounted in the main product tank.

Chemical transfer pump (4000 & 5000L only)

The 12 volt chemical transfer pump has an open flow of up to 40 l/min and can transfer chemical from any container using a probe or envirodrum coupling.

The chemical transfer pump features an optional integrated flow meter to keep track of how much chemical has been transferred, providing a completely stand-alone transfer system at the flick of a switch.