Description

STD MANURE SPREADER – STANDARD EQUIPMENT

EM BUFFALO have an extensive range of standard equipment. Thanks to this, the spreader fulfils the requirements of even the most demanding conditions.

- Loading chest made from quality metal sheet S355J2+N – 6 mm thick

- Double-chain conveyor – Ø 14 mm with 28 t breaking capacity per chain

- Floor bars with a closed profile

- Hydraulic stepless chain floor conveyor

- Air or hydraulic brakes

- A single truck axle with a cross-section of 150 mm

- Mechanically adjustable single axle

- Mechanical support foot

- Inspection ladder

- Stepless gearbox

- PTO shaft

- Connections for corn extensions

- Foot inside the loading chest

- LED lights

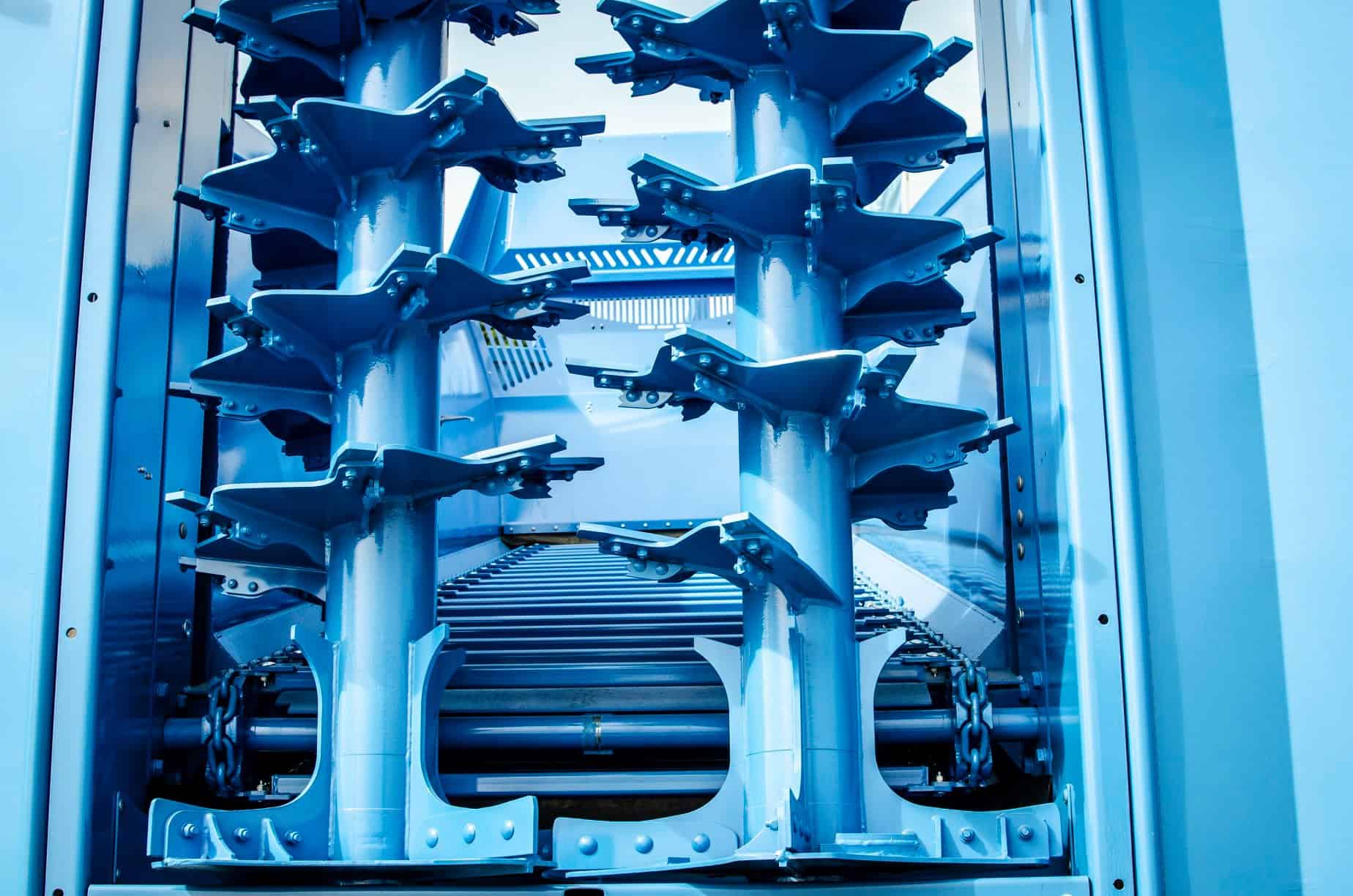

STANDARD BEATER

In all our manure spreader models we have used an innovative beater characterised by a massive construction and compact folds welded both sides with a continuous double-sided weld.

- Made from quality steel S355J2+N

- Double-drum 2.0 m high

- Beater weight – 850 kg

- Speed of beater rolls 426 rot/min

- Speed of PTO shaft 540 rot/min

- Rollers with cross-section of Ø 180 mm and 8 mm thick walls

- Replaceable cutting knives made from HARDOX steel 12 mm thick (35 pcs per roll)

- Distance between knives – 30 mm

- replaceable spreading paddles (35 pcs per roll)

- Bottom plates with a diameter of 800 mm

- replicable paddles for lime spreading

- Oil sight glass

- Central lubrication of top bearings

- Grip for detaching the beater

COMFORT

Additional safety during transport is guaranteed thanks to air or hydraulic brakes.

Air-brake system is characterised by the best brake force. Manure spreader can be equipped in a 1-circuit or 2-circuit system. Hydraulic brakes are less popular with our customers.

If a manure spreader is to operate with a few tractors, a mixed brake system may be used.

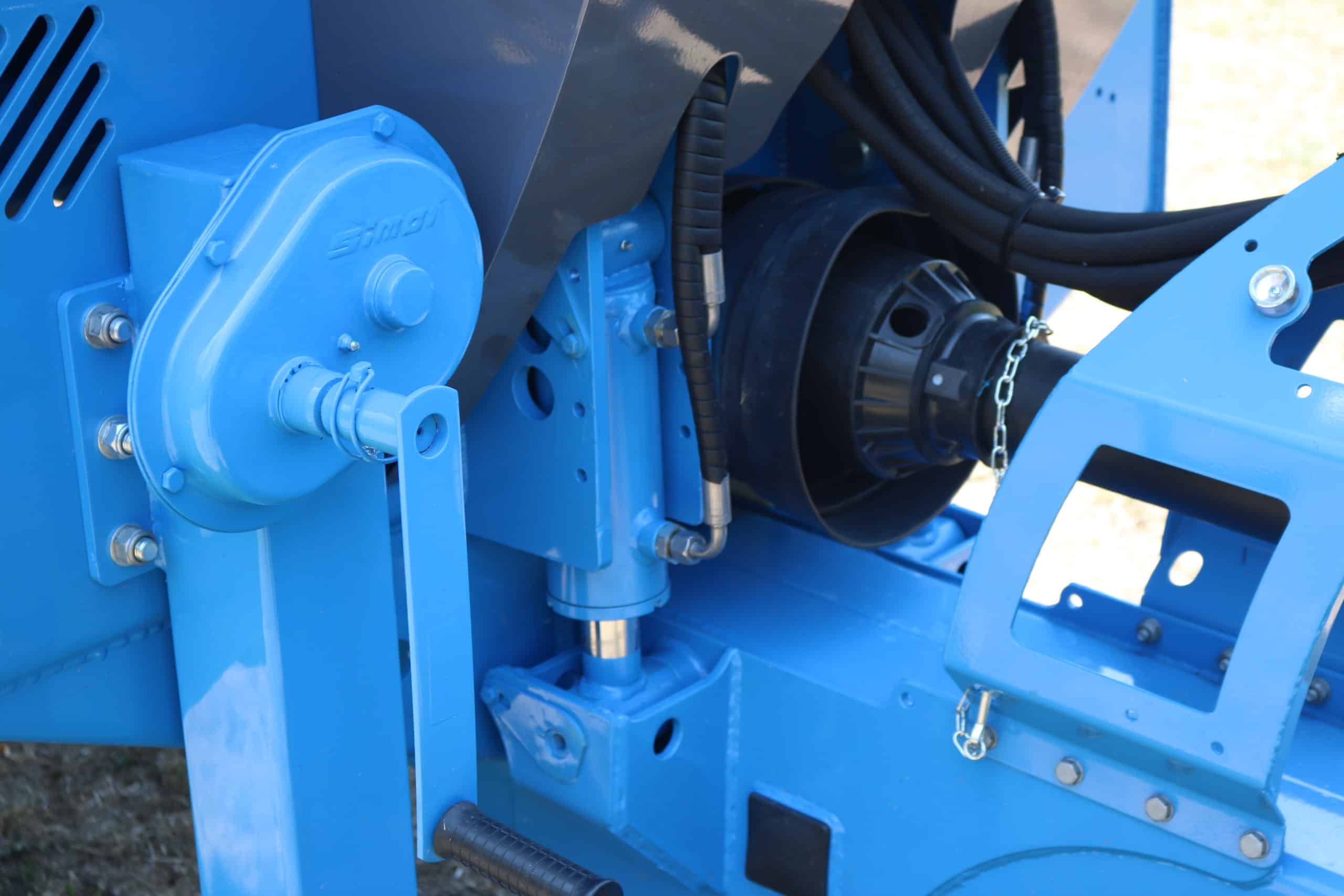

EM BUFFALO MANURE SPREADER – HYDRAULIC DRAWBAR SUSPENSION

Hydraulic cushioning of a drawbar affects the comfort during transport and during manure spreader work. It minimalizes shocks when on an uneven terrain. Standard cushioning has to actuators attached to hitches 20 mm thick.

Advantages of hydraulic drawbar suspension in a manure spreader:

- Possibility of using a double anti-balance force (on an empty and loaded machine)

- Regulation of cushioning level

- Larger clearing (2 actuators placed on the top of the hitch)

- Cushioning control (indicator on the outside of the spreader)

TRAILER

The option of converting the manure spreader into a capacity trailer is a great addition if it comes to the transport of crops. This solution allows for using the spreader functionality in full and decreasing the costs during harvest.

The unloading is fast, simple and without leaving any material on the trailer. The speed of feed is a stepless regulation taking place from the tractor cabin.

CONTROLS

The manure spreader is controlled thanks to tractor hydraulics. In case there are not enough hydraulics sections, a splitter can be used as well as additional control levers.

ELECTRONIC CONTROLS

The electronic control panel for BUFFALO manure spreaders that guarantees a simple use and an efficient operation.

Main benefits of electronic control BUFFALO manure spreader, equipped in an electronic control possess:

- Hydraulic splitter in standard (1 section of hydraulics required)

- Large and clear display

- Comfortable placement of keys makes it easy to access certain functions

- Menu

- Panel cover protecting electronic wiring from any shocks, dirt or humidity

- Comfortable manure spreader control directly from the tractor cabin

MANURE SPREADER – TIRES

In all models there is a possibility to choose the type of chassis – single axle, tandem (double chassis) or torsional tridem. Every customer can match the size of tires according to their needs or conditions in which the machine will be operating. Tandem chassis improves the stability and decreases the ground pressure.

For more please download our catalogue in download tab.

* This data is only for your information. The technical specification from the table may be subject to change.